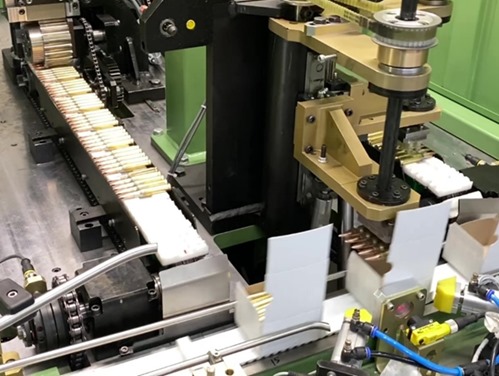

The priming machine is a critical part of the ammunition production. The priming process has a direct impact on ammunition quality, especially when it comes to firing. The priming machine is designed to insert small arms of military ammunition with berdan or boxer-type primers at a high capacity. Military ammunition producers that use this priming machine benefit from its high speed, conversion tool kits for multiple calibers, durable framework, safety features, inspection and quality control instruments, and most importantly, ease of use and maintenance.

The capacity of the priming machine is 240 parts per minute. Actual capacity highly depends on the quality of the cartridge cases fed to the system. The higher the quality of the cartridge cases the higher the net throughput of the priming machine will be. Usually, the efficiency of the priming machine is calculated %85. Therefore, the minimum net throughput of the priming machine is 200 parts per minute.

Ammunition producers can run multiple calibers on this priming machine by replacing the tool kits. Any center-fire small arms calibers can be inserted with primers in this priming machine including pistol and rifle calibers. Small arm calibers up to 338 Lapua including blank cartridges can be inserted with primers in this priming machine. The conversion tool kits are designed and produced by Yeter Makina. Therefore, we can supply parts or a whole new kit for an additional caliber as long as the machine is in use.

Lining Machine Production

The priming machine is designed for military ammunition production. It is built following the ATEX Directive considering the amount of explosives and gunpowder handled in military ammunition production facilities. The priming machine is equipped with ex-proof components and is certified. Further safety precautions are taken to ensure operators’ safety.

The priming machine performs complete quality checks on components to eliminate elements that could lead to misfiring. When the primers are boxer type the primers are checked to make sure that the primer anvil exists and is correctly positioned. Cartridge cases are inspected with their mouth and the flash hole before they are transferred to the primer insertion station. The priming machine performs a primer crimping right after primer insertion. Finally, the inserted primer and its crimp are checked with a camera followed by a primer depth check.

The priming machine is designed for a minimum level of physical human interaction with the machine. It is controlled through an HMI touchscreen. The software of the priming machine will pop up messages on the HMI screens to guide operators in certain occurrences. The real-time production amounts will be indicated on the HMI screen and all the alarms and feedback regarding the situation of the stations will be listed. In case any jams occur, operators can observe the HMI screen for the location of the jam. There are several precautions to protect the priming machine and its parts when a jam occurs. The system is embedded with over-current detection and encoders to stop the system immediately. Thanks to the advanced software of the priming machine one operator can use multiple priming machines at the same time.

https://www.yetermunitions.com/en/ammunition-assembly-machines/primer-inserting-machine

Magazin Name Güncel Magazin Haberleri

Magazin Name Güncel Magazin Haberleri